Published on

“Humanoid robots designed for different tasks can now share a single artificial intelligence ‘brain’ that coordinates their actions across multiple locations simultaneously.”

A UK-based company has unveiled an AI system that can virtually work as a “shared brain” for fleets of robots built for different purposes across factories, services, and homes simultaneously.

Companies like Tesla, Boston Dynamics and XPeng have showcased humanoid robot prototypes in recent years, but these demonstrations typically feature robots operating on their own.

The UK firm’s approach is designed to manage multiple humanoid robots together under a single AI.

Shared control systems are already common for industrial robots, however, applying the same approach to robots that rely on human-like movement and manipulation has been rare.

The AI system, called KinetIQ, can assign tasks to entire robot fleets and control individual movements simultaneously in seconds, according to Humanoid, the robotics company behind the new system.

Data from individual robots is shared across the system, helping improve performance fleet-wide.

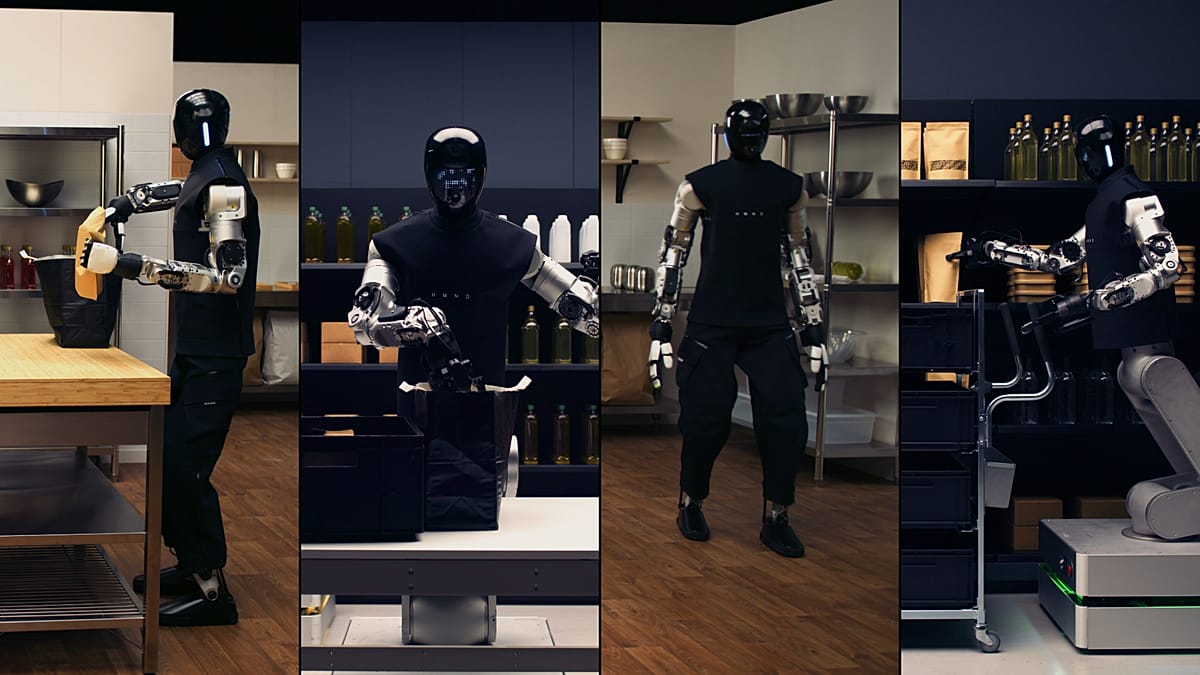

In a video released by Humanoid, a woman asks a bipedal humanoid robot to order cocoa powder and olive oil. In the next scene, wheeled robots in a warehouse-like environment use five-fingered hands to grasp a glass bottle and a soft paper bag, and then put them in a hard container box before packing them into a paper bag.

Once the order reaches the home, the bipedal robot unpacks the bag and places the items as instructed by the woman’s voice commands.

According to Humanoid, the wheeled robots seen in the video are designed for industrial use, such as back-of-store grocery picking, container handling and packing, while the bipedal robots are intended for service roles and domestic use.

The company describes the bipedal robot as an “intelligent assistant” capable of voice interaction, online ordering, and grocery handling.

Humanoid has previously managed to have a 179 cm bipedal robot walk in just two days after its assembly, a process that typically takes weeks or months in humanoid robotics.

The robot is designed to carry loads of up to 15 kilograms, with the company positioning it as a response to labour shortages, physically demanding work and unpaid domestic care.

Humanoid said the capabilities shown in the video have already been tested in real-world pilot projects, and that a beta version of the wheeled robots will be available for sale early next year.

For more on this story, watch the video in the media player above.

Video editor • Roselyne Min