Like their fossil-fuelled contemporaries, electric cars and their components have a finite lifespan. How long will an EV realistically last before it fails completely?

Welcome to The Switch, Euronews Next’s new mobility series for people considering making the switch to an EV.

As the pace of electrification quickens amid a growing climate crisis and an uncertain economic outlook, we’ll be your companion as you make the transition from your fossil-fuelled car to electric.

Each week, we’ll offer guidance and insights from industry experts as well as aim to demystify the process and dispel misinformation.

As electric vehicles (EVs) continue to gain popularity, the role of the circular economy in reusing and recycling their components is becoming increasingly important.

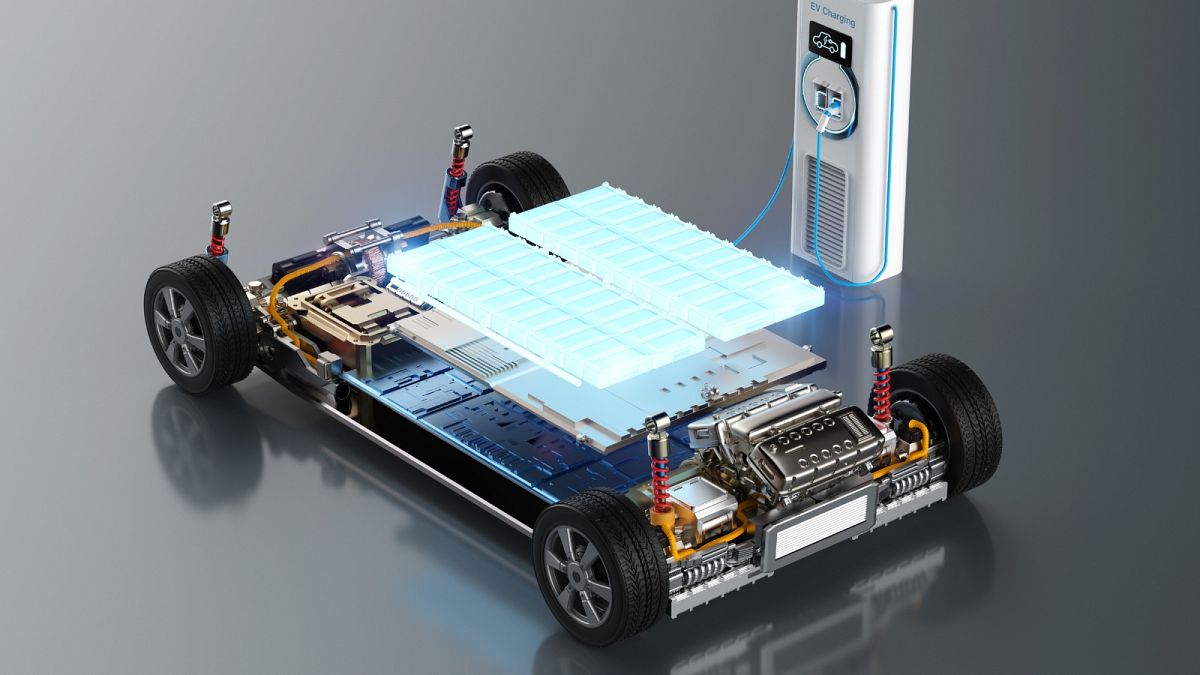

EV batteries have a finite lifespan and gradually undergo degradation – a process of chemical and physical changes that reduce their ability to hold a charge over time.

As a result, battery performance diminishes with age, raising important questions for potential buyers of new or used battery EVs regarding battery longevity, the durability of their components, and the options when it reaches the end of its life.

Lifespan of battery electric vehicles (BEVs)

Modern EVs are designed to last 15-20 years, comparable to or even longer than traditional internal combustion engine (ICE) vehicles.

The key factor in their longevity is the battery. EV batteries are typically considered at the end of their life when they drop below 70 to 80 per cent of their original capacity.

However, advancements in battery technology suggest that many EVs now sustain their performance well beyond this capacity threshold, so using this benchmark to determine the end-of-life for lithium-ion batteries may well become outdated in the future.

Many car manufacturers offer warranties for an average of eight years or 160,000 km, but real-world data shows that batteries often last much longer.

Battery replacement: Timing and Costs

Battery replacement is the most significant expense associated with owning an EV.

While early EV models showed faster battery degradation, contemporary batteries, with improved technology and management systems, are now much more durable than before.

If a battery issue does arise, it’s often possible to replace individual cells or modules rather than the entire battery, saving both money and resources.

A study by Recurrent in the US found that EV battery replacements are uncommon, with only 2.5 per cent of vehicles requiring replacements across all years and models, excluding major recalls.

However, if a full battery replacement is necessary, costs can vary widely across Europe depending on the vehicle model, battery size, and country, as prices are influenced by differences in labour costs and local market conditions.

In Germany, the cost of replacing an EV battery ranges from €4,500 to €18,600, depending on factors such as the battery’s type, size, and the vehicle’s manufacturer. This price variation highlights the broader trend across Europe, where EV battery replacement costs differ significantly among models and countries.

For instance, among Tesla vehicles, the Model 3 generally offers the most affordable replacement option, while the Model S and Model X are positioned at the higher end of the price spectrum.

Other brands like BMW and Nissan also have a wide range of costs.

The UK, for example, typically has higher average replacement costs compared to Germany and France.

Although these costs are significant, prices are expected to decrease over time as battery technology continues to evolve and production scales increase.

The circular economy

As EVs reach the end of their life, the circular economy offers a sustainable way to extend the life of their components, particularly batteries.

Even after they can no longer power a vehicle, high-voltage batteries often retain significant capacity.

For now, these batteries can be repurposed for less demanding applications, such as stationary energy storage systems. This second life not only extends the battery’s usefulness but also conserves resources and reduces environmental impact.

However, repurposing comes with challenges, including ensuring the reliability and safety of second-life batteries.

There’s also a trade-off with repurposing. While it delays the need for recycling, allowing the industry to mature and reduce the risk of illegal disposal, it also postpones the recovery of valuable materials needed to advance recycling efforts and reduce reliance on new raw material extraction.

Recycling and material recovery

Once EV batteries are no longer viable for any use, recycling becomes crucial. Lithium-ion batteries contain materials like lithium, cobalt, and nickel that can be reclaimed, reducing the need for new mining.

Advanced recycling methods, such as hydrometallurgy and pyrometallurgy, can recover these materials at high efficiencies.

Several battery recycling plants are now operating across Europe, including the newly opened facility by AE Elemental in Zawiercie, Poland, which prioritises sustainable practices and material recovery.

Beyond batteries, other EV components – such as electric motors – are rich in copper and rare earth metals and can also be recycled or refurbished for use in new EVs or industrial machinery.

However, challenges remain, including the need for standardised processes to ensure efficiency and sustainability.

Future trends in battery tech

As concerns over material scarcity and costs grow, many carmakers are shifting towards lithium iron phosphate (LFP) batteries.

These batteries are more affordable to produce and are also more durable and safer, though they typically store less energy, leading to shorter driving ranges.

Solid-state batteries, which replace the liquid electrolyte with a solid ceramic material, are another promising development. They offer potential benefits in terms of safety, energy density, lifespan, and environmental impact. However, mass production of solid-state batteries is still several years away.

As EVs become more mainstream understanding their end-of-life process is vital for sustainability. When batteries reach their end of life, repurposing and recycling become crucial.

Looking ahead, advancements in battery technology, such as cobalt-free lithium iron phosphate (LFP) and solid-state batteries, promise to enhance durability, safety, and efficiency.

While challenges remain, the continued evolution of EV technology and recycling infrastructure is paving the way for a greener, more sustainable future.

- Geraldine Herbertis the motoring editor for the Sunday Independent newspaper and an e-mobility expert.